-40%

3D Printer Adhesive Glue Bed Weld Original, Strong Grip Reduces Warping for ABS,

$ 19.5

- Description

- Size Guide

Description

THERMAL DYNAMIC COATING - Based on science, works like magic; Parts stick at hot and release when cooled; Dries fast and non tacky so it won't clog your nozzle with gooLONG LASTING - Print several times on a single coating; recharge with a wet sponge to get more prints out of a single application; Cost pennies per print

LOW ODOR & WATER SOLUBLE - No harsh smells; No headaches; Easy to touch up or remove with water

NO-MESS APPLICATOR - Built in foam tip makes applying the coating to your build plate surface simple and it won't accidentally spill

90-DAY MANUFACTURER GUARANTEE - If this solution does not work for your 3D printing application, you have a FULL 3 MONTHS to contact us for a 100% money-back refund

Do you have trouble with parts warping or coming detached from the printer bed?

Have you struggled with part removal after your print is finished?

Introducing BED WELD - ORIGINAL™

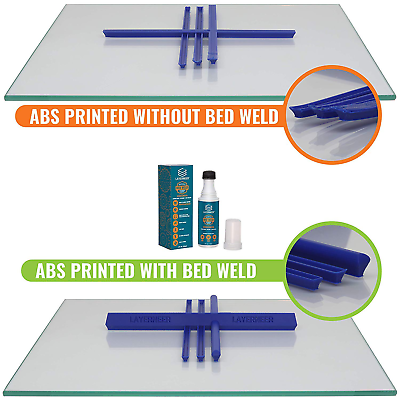

BED WELD was engineered to solve these challenges by enhancing your print surface so that it grabs hold of that critical first layer when your build surface is hot, and refuses to let go with its gecko like grip. In many cases you can often print without rafts or build plate adhesion layers, saving you time and material.

Once your print is done the coating dynamically morphs as your printer bed cools, and releases its hold so you don't have to wrestle to get your part off.

No more chipped glass or broken parts. In most cases, your part will fully detach without the need for tools. If your part does remain attached it normally takes just a simple lifting of a corner using the edge of a razor, and the part easily pops off.

BED WELD comes with a unique applicator that makes applying the coating a simple no mess process. The coating dries quickly to form a thin film that is not sticky, so there is no risk of getting a clogged nozzle or having residue on your finished part.

NOTE:

The BED WELD coating was designed for use with heated build plates made from glass. It was optimized to work with PLA, ABS, PETG, and CPE filaments. BED WELD is not recommended for use with Nylon, PP, or TPU 95A. See image for compatibility summary.

Applying to glass build plates that have Microporous coatings, or flexible magnetic beds, is not supported.

Do not apply BED WELD directly to aluminum bed surfaces. First, place a layer of Kapton tape over the aluminum bed surface and apply BED WELD on top of the Kapton.

When printing with ABS we recommend setting your bed temperature no higher than 80C.

BED WELD is backed by an unconditional 90-Day money back manufacturers guarantee so you risk nothing!