-40%

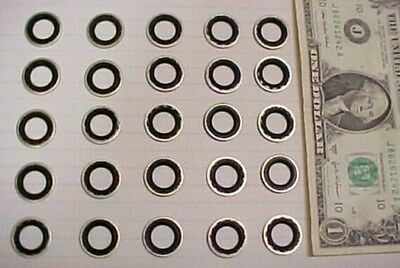

Lot 25 Parker Statoseal Washers Stat-o-Seals 7/16" -4 AN Hydraulic Seals Gaskets

$ 5.27

- Description

- Size Guide

Description

1345H2A.08New Parker Stat-O-Seal Sealing Washers, Size 7/16" or -4 Hydraulic Fittings or NAS1523 Fastener Size -7; Possibly Part Number NAS1523-7B. Each bid quantity is for a Lot of Twenty-Five (25) Seals. You may bid / buy any number of lots, up to the total quantity available above.

Very expensive stuff -- several bucks per

pair

normally -- but very useful for sealing around hydraulic fittings, heads of bolts, plugs, etc. They will not only 'keep the rain out' but they will also keep your high pressure hydraulic fluid

in

. Stripped out a drain plug? Just weld up the old one, then drill and tap a new one wherever you want it. Slide one of these onto a 7/16" washer head bolt, torque it down, and you're done. Bolt things onto pressurized tanks or bolt pressurized tanks onto things, without having to worry about leaks. If you have ever tried to seal something with an ordinary o-ring, you know that it usually squirts out the side when you apply even a moderate amount of pressure. With these you can crank them down about as much as the bolt will stand, because the rubber is encased in steel and it's not going anywhere.

These were acquired in a big load of salvage freight last year. As is the custom, the liquidator tore off all the identifying labels before they shipped everything. They were being shipped in large plastic bags in a box with "

Strat

oseals" written with a black magic marker. We re-bagged them into lots of twenty-five pieces for resale. I ran all the numbers on the bag labels through Google and didn't get a hit on anything. We finally concluded that the part number must be a

customer

part number rather than a Parker part number. Back at the Parker website, the only Stat-o-Seal we could find that matched the characteristics of these (dimensions, color, material, etc.) was a NAS1523-7B, which is basically an aircraft and aerospace part. Armed with nothing more than that information and a set of calipers, we came up with the following:

Outside diameter: .750" (3/4")

Inside diameter: .435" (approx.)

Thickness (metal casing): .050"

Thickness (rubber): Drops out of the calipers at .082"

Casing material: Probably 4130 Chrome Moly (attracts a magnet, I can't bend it with my fingers, and it's not aluminum or stainless)

Seal material: Probably Buna-N (aka Nitrile, according to Parker's color-coded system)

Pressure rating: 6,800 PSI

This is what is on the bag labels:

PART NUMBER 204248 (a "P" in a circle, with 4 numbers which vary from one bag to the next)

QTY: 1250 N.EMPLEADO

CBI: 3455496-3 (4 digits, different on each big, possibly a lot tracing number)

T I 10 - 27 - 06 (some bags have it, some do not)

According to the manufacturer:

Introduction

Most fluid systems have fasteners that must be sealed. Parker’s fastener seal designs found in the Stat-O-Seals and ThredSeals feature an elastomeric sealing element molded in place within a metal retainer (washer). Although resembling a simple o-ring groove concept, the mold in place fastener seal offers numerous advantages. Ideal for sealing small and miniature sizes, the Parker Lock-O-Seal is a two-piece combination seal comprising a separately molded o-ring fitted within a surrounding metal washer. Other speciality fastener seals are also available.

Stat-O-Seals

-- Intended to seal the shank of a bolt immediately under the head

-- 600 Series: Intended for sealing standard series fasteners

-- NAS1523 Series: Applications that require conformance to NAS1523

-- 610 Series: Intended for sealing metric fasteners from 5mm to 22mm

ThredSeals

-- Intended for sealing directly on the fastener threads

-- 750 Series: Intended for sealing most UNC and UNF threads

Lock-O-Seals

-- 800 Series: Intended to seal the shank of a bolt immediately under the head

-- Ideal for sealing small and miniature sizes

-- Special material combinations not available as a 600 Series Stat-O-Seal

Specialty Products

-- Fastener seal kits -- 250 Lock-O-Seals for sealing straight tube fittings and banjo style fittings

-- Food, beverage and FDA related applications

-- Custom designed fastener and fitting seals

Stat-O-Seal

How the Stat-O-Seal Works

The Stat-O-Seal is designed with a pre-calculated interference factor built into the teardrop shaped elastomeric seal. The cross section free height of the rubber is greater than the metal retainer, providing the proper compression without squeezing the seal beyond its elastic limit. As the fastener is installed into the mating hardware, the Stat-O-Seal is compressed down to the retainer thickness. The retainer provides a positive alternate load path for fastener torque and forms a protective gland area for the confinement of the seal in a controlled state. Since the elastomer seal cannot move outward, the mass of the seal is forced inward against the shank of the fastener and against the mating surfaces, creating a positive seal. This principle is known as controlled confinement sealing. The diameter of the fastener head should always exceed that of the maximum “E diameter” (see dimensional sketch on page 5) in order to preserve this principle.

Stat-O-Seal Features

Parker Stat-O-Seals are one-piece, molded-in-place seals with the rubber sealing element mechanically and/or chemically bonded to the metal retainer. Parker’s “Splined and Coined” mechanically bonding feature is used on many 600, NAS1523 and 610 series sizes. This feature ensures a positive attachment of the rubber to the retainer, eliminating missing or loose seal elements associated with bonded seals. Stat-O-Seals are designed to seal beneath the head of the fastener as shown for both internal and external pressure and vacuum systems. Stat-O-Seals offer users long and reliable service, a high degree of reusability and easy assembly. The Stat-OSeal’s unique features provide many advantages and benefits as shown below:

-- No machined O-ring grooves are required in the mating flange

-- Precisely controlled optimum percent squeeze eliminates over compression

-- The retainer edge is visible after installation allowing for easy visual inspection and reducing failures caused by missing seals

-- The ridged self centering design provides easy and accurate placement of the seal

-- The solid metal to metal contact improves joint stability and eliminates re-torquing

-- Long reliable service and a high level of reusability

-- Rubber/bolt interference provides for easy assembly

Stat-O-Seal High Pressure Considerations

Maximum Pressures Guidelines

The operating pressure of a Stat-O-Seal must be kept well below the pressure at which the retainer metal would rupture. The tables on this page give the maximum recommended internal operating pressure for 600 and 610 Series Stat-O-Seals as determined by hoop stress calculations. A safety factor of 3 was used along with the tensile yield strength for low carbon steel and chrome moly steel.

Although 7075-T6 is used for the aluminum retainers the actual material temper may vary on parts containin certain elastomers due to exposure to heat during processing. A safety factor of 4 was used when calculatin the maximum safe operating pressure for aluminum to account for this variation. A safety factor of 2 was use for 304 stainless steel (annealed) due to the large differential between yield and ultimate strength.

All of the values assume adequate joint integrity to preclude flange separation and are based on static pressure. Metal fatigue should be factored in when necessary Consult the factory for more information on sealing external pressures, vacuum service, or when sealing gaseous pressure greater than 200 psi.

Bolt Torque for High Pressure Applications

High pressure fluids acting under the head of a bolt tend to stretch it, lifting the bolt head off its seat. When this happens, the space exposed under the bolt head can permit the Stat-O-Seal elastomer to extrude and fail. It is, therefore, important in high pressure applications to torque the bolt well at assembly, providing enough prestress in the bolt to prevent stretching.

Clearance for Extra Rubber

Stat-O-Seals have some excess rubber (see recommended diametrical clearance), and clearance must be provided to receive it. In low pressure applications, this clearance may be either in the mounting surface or in a washer between the bolt head and the Stat-O-Seal. In high pressure applications, however, the normal clearance must be on the high pressure side of the Stat-O-Seal, with little or no clearance on the low pressure side. Otherwise, the fluid pressure will extrude too much rubber into the clearance gap, resulting in a leak.

Stat-O-Seal Recommended Fastening Torque

When fastening torques are discussed by engineers there is often controversy. There are many variables such as wrenching methods and thread friction (influenced by lubrication, plating, surface finishes, length of grip, class of thread, etc.) that may influence the load applied to a fastener.

Parker Stat-O-Seals provide a certain amount of latitude when it comes to torque requirements. Actually, Stat-OSeals are capable of sealing low pressures when only finger tight.

When using a Stat-O-Seal the fastener should be torqued adequately to prevent joint separation when the system is pressurized and below the level at which the fastener or Stat-O-Seal retainer will yield. The tables on this page show a recommended range that will work for most Stat-O-Seal applications. The torque values displayed in the table may exceed the permissible torque values for many fastener materials. Contact your fastener supplier for the recommended torque limits of your fastener. Consult the factory for sizes not shown.

Lubricants are not required when installing Stat-O-Seals. If a lubricant is used, be sure it is compatible with the elastomer selected.